Sump - removal and refitting

Note: New gaskets and sealing strips must be used on refitting.

Removal

1 Disconnect the battery negative lead and

drain the engine oil (see Chapter 1).

2 Refer to Chapter 5, Part A and remove the starter motor.

3 Unbolt and remove the clutch cover plate.

4 Extract the sump securing bolts and remove the sump. If it is stuck, prise it gently with a screwdriver but do not use excessive leverage. If it is very tight, cut round the gasket joint using a sharp knife.

Refitting

5 Before refitting the sump, remove the front

and rear sealing strips and gaskets. Clean the

mating surfaces of the sump and cylinder

block.

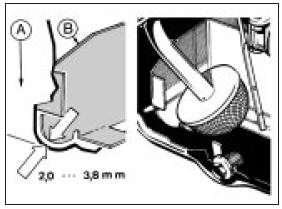

6 Stick new gaskets into position on the block using thick grease to retain them, then install new sealing strips into their grooves so that they overlap the gaskets (see illustrations).

5.6a Sump gasket fitting details at timing cover end (A) and flywheel end (B)

5.6b Fitting the sump gasket sealing strips to overlap the tabs on the gasket

7 Before offering up the sump, check that the gap between the sump and the oil baffle is between 2.0 and 3.8 mm (see illustration).

5.7 Sump and oil baffle clearance details

A Sump B Baffle

8 Screw in the sump bolts and tighten in three stages to the specified torque in the sequence shown (see illustration).

a) Stage 1- in alphabetical order b) Stage 2 - in numerical order c) Stage 3 - in alphabetical order

5.8 Sump bolt tightening sequence

9 It is important to follow this procedure in order to provide positive sealing against oil leakage.

10 Refit the clutch cover plate and the starter motor and reconnect the battery.

11 Refill the engine with the correct grade and quantity of oil.

See also:

Alternator - removal and refitting

Removal

1 Disconnect the battery leads.

2 Disconnect the multi-plug, or disconnect

the wires from their terminals on the rear of

the alternator, noting their locations (as

applicable), then slack ...

Accelerator pedal - removal and refitting

Removal

1 The pedal can be removed once the throttle

cable has been disconnected from it as

described in Section 7.

2 Undo the two pedal support bracket

retaining bolts and remove the pedal.

Ref ...

Front seat air cushion assembly - removal and refitting

Complete assembly - removal and

refitting

1 Remove the seat.

2 Straighten the seat back cover retaining

tangs, and pull the cover upwards to expose

the air cushion.

3 Cut through the four securi ...